The user-friendly system for automatic cutting to length and laying of upholstery backing material made of fleece, felt, coir or similar materials.

Polsterträgeraufleger

The Upholstery backing feeder cuts the backing material from a roll and places the cut backing on the foam sheet. The upholstery backing material is pulled by the gripper from the material roll to the set/calculated dimension. The upholstery backing material is then cut off and positioned on the lay-up belt. The lay-up belt is lowered. During the plate transport onto the following conveyor belt, the upholstery backing is placed onto the foam board by the driven lay-up belt.

An optional gluing bridge allows to apply hot melt glue to the foam board beforehand, so that the upholstery backing is directly glued to the board. The optional two-sided feeding of the upholstery backing material allows the use of different materials.

The Upholstery backing feeder can be used for the production of various types of multilayer upholstery.

The simple production of different spring mattresses with upholstery backing materials are common fields of application.

Future viability through continuous further development

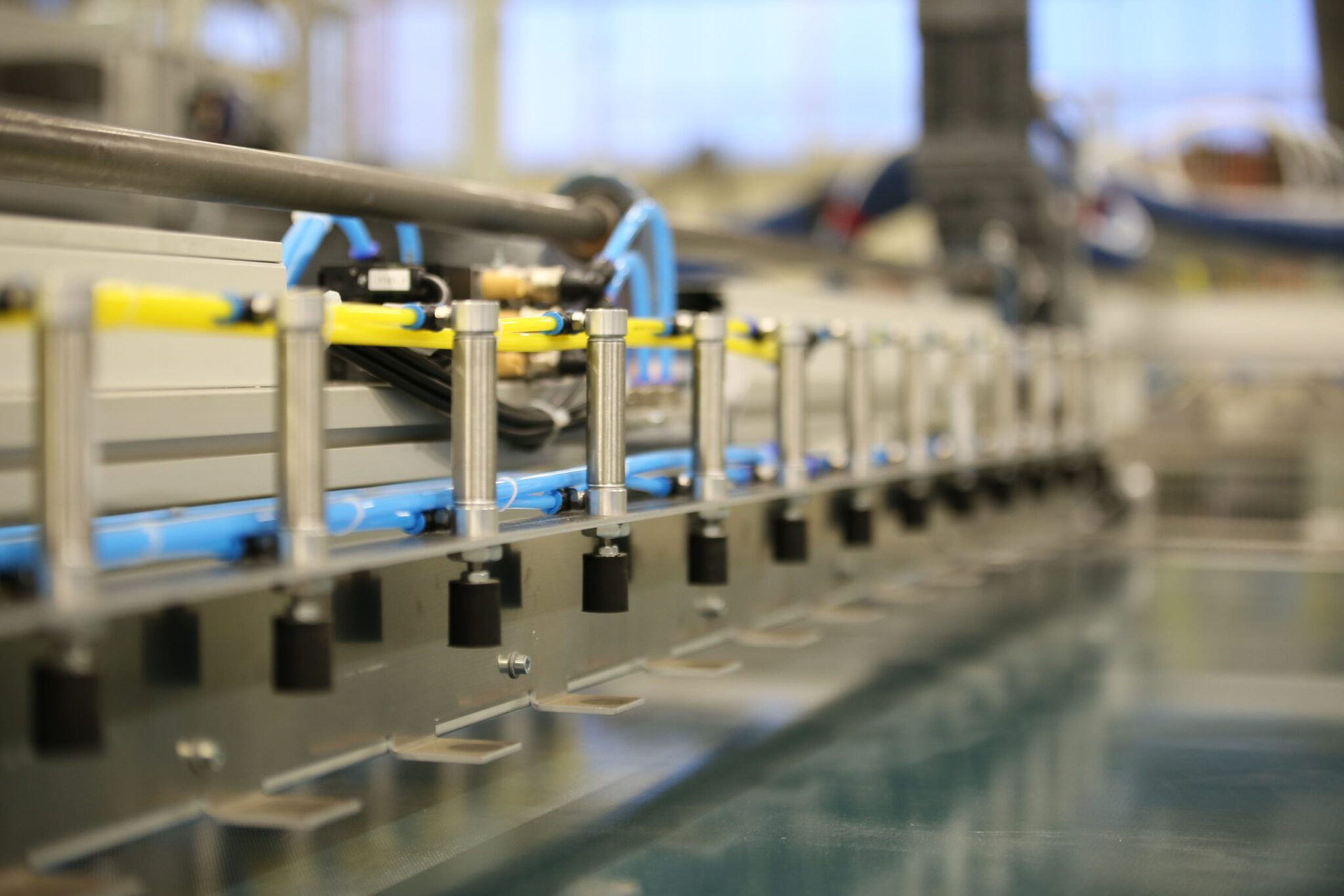

Automatic cutting to length of the upholstery backing from the roll and precise positioning by longitudinal and transverse alignment.

With detection of the end of the material and constant tensile force by dancer shaft buffer.

We are constantly developing our proven technology for your profit.

Upholstery backing width (cut): 50 cm-190 cm

Precise positioning due to longitudinal and transverse alignment

Driven lay-on belt

Silicone-coated conveyor belt with wedge guides for foam board transport

Driven material unwinding

Sensor-supported detection of the end of the material

constant pulling force due to dancer shaft buffer

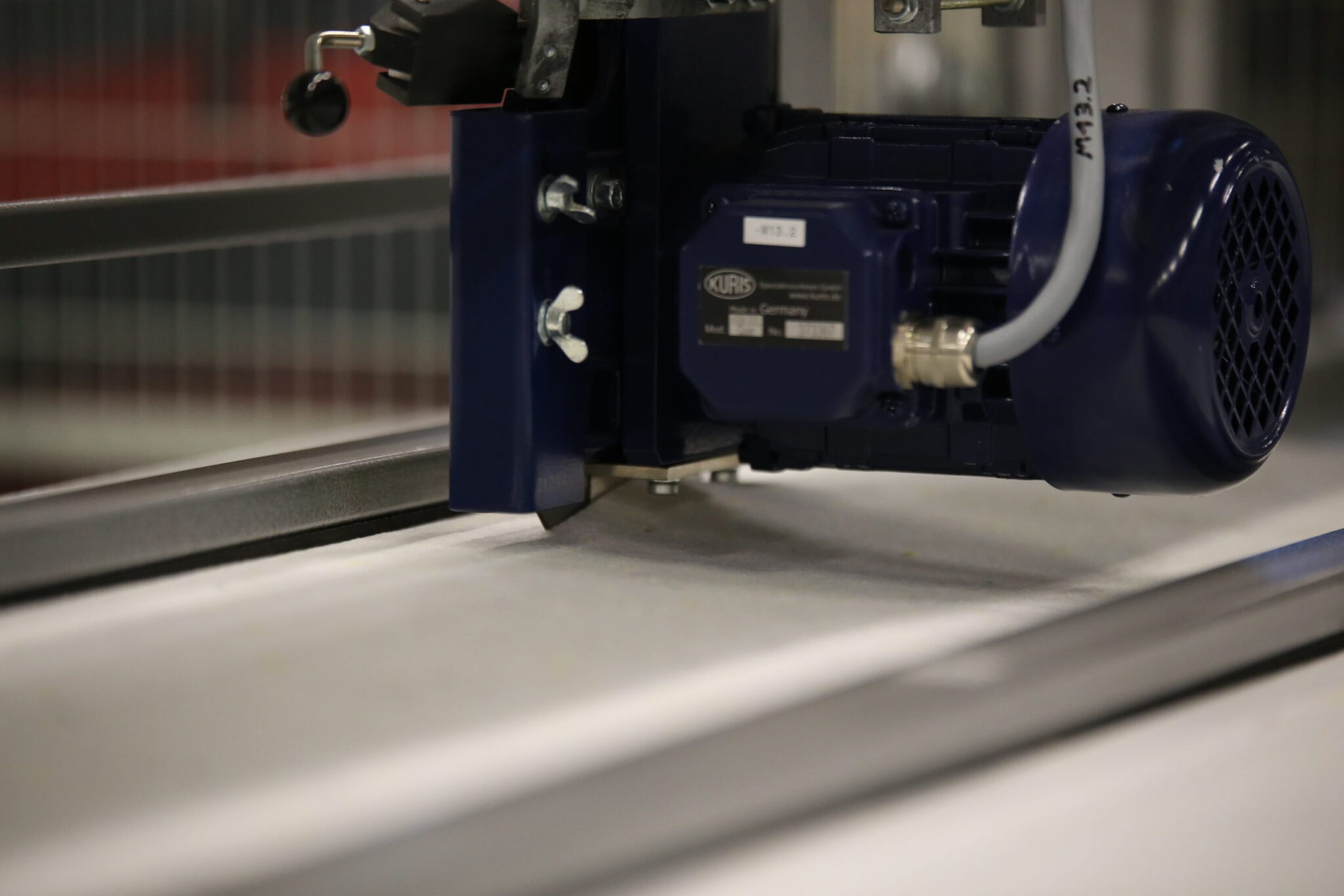

Four-sheet knife with grinding device

Low-jerk frequency converter drives with thermal contacts (full motor protection)

Hotmelt gluing bridge for direct gluing to the foam board

Zufriedenheit ist unser Fortschritt

Weltweit werden KSM-Crossliner für die Matratzenproduktion eingesetzt.

Die einzigartige starke Klebeverbindung des KSM-Crossliners macht ihn zum Lieblingsprodukt in der weltweiten Matratzenproduktion. Die einfache und bedienerfreundliche Handhabung der Maschine sowie die individuelle flexible Möglichkeit der Zusammenstellung mit weiteren Produktionsmaschinen sind herausragende Features für unsere Kunden. Innovative Techniken und jahrzehntelange Erfahrung geben Ihnen Sicherheit.

step to the solution!

You can reach us in different ways, depending on which type of contact you prefer.