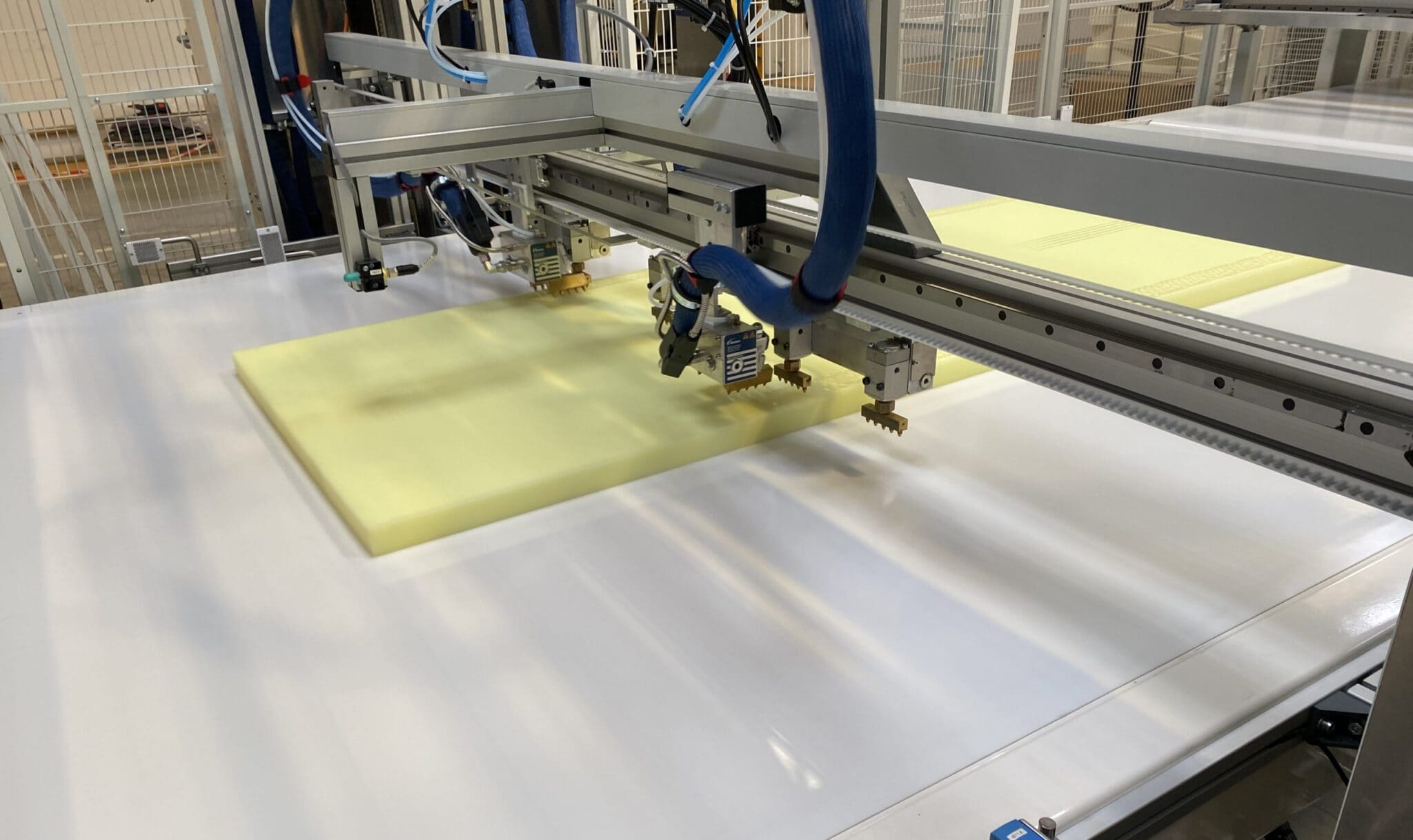

The Crossliner gluing system is a user-friendly system for the automatic application of hot-melt adhesives to rectangular sheets of foam, coconut, felt or similar materials.

Crossliner

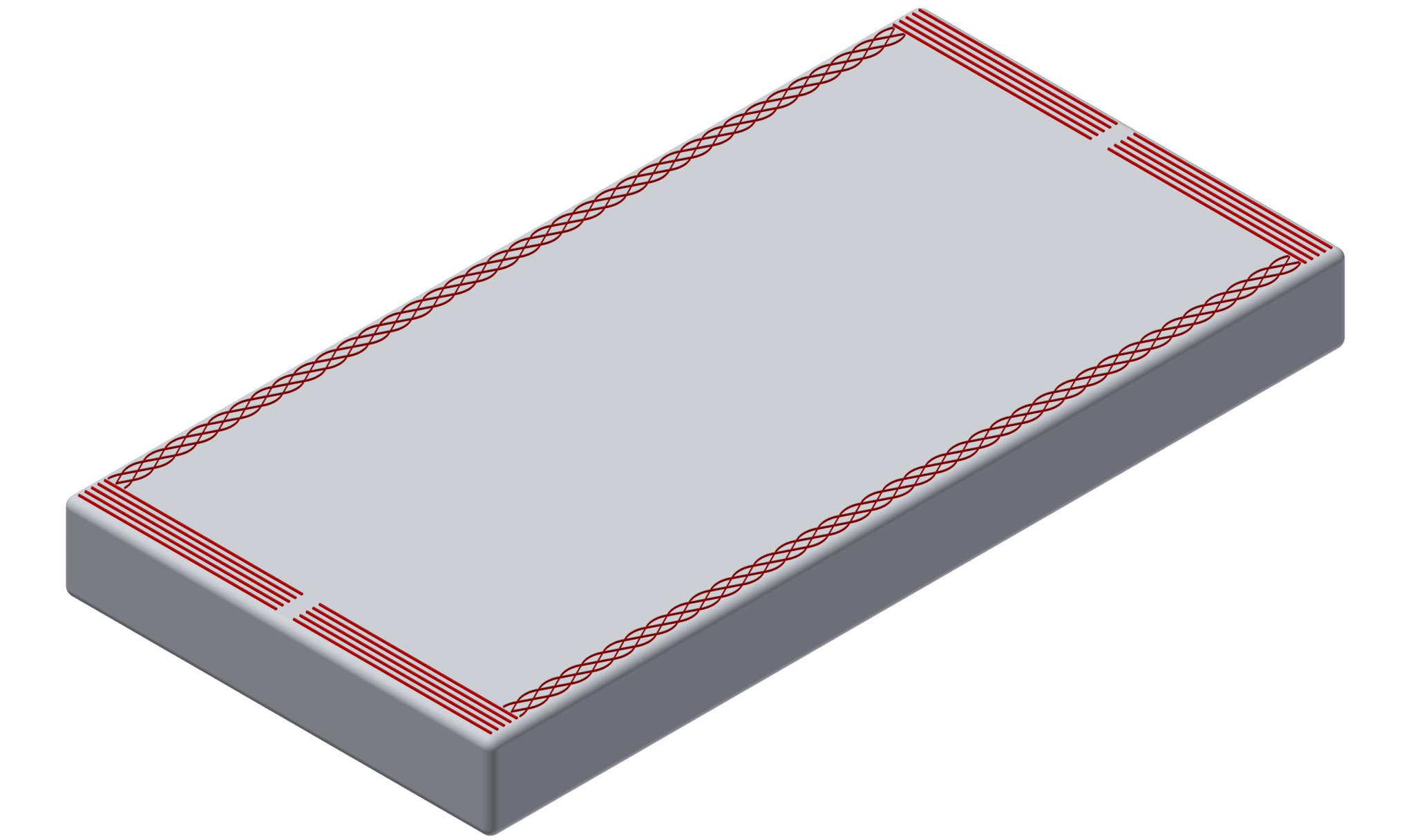

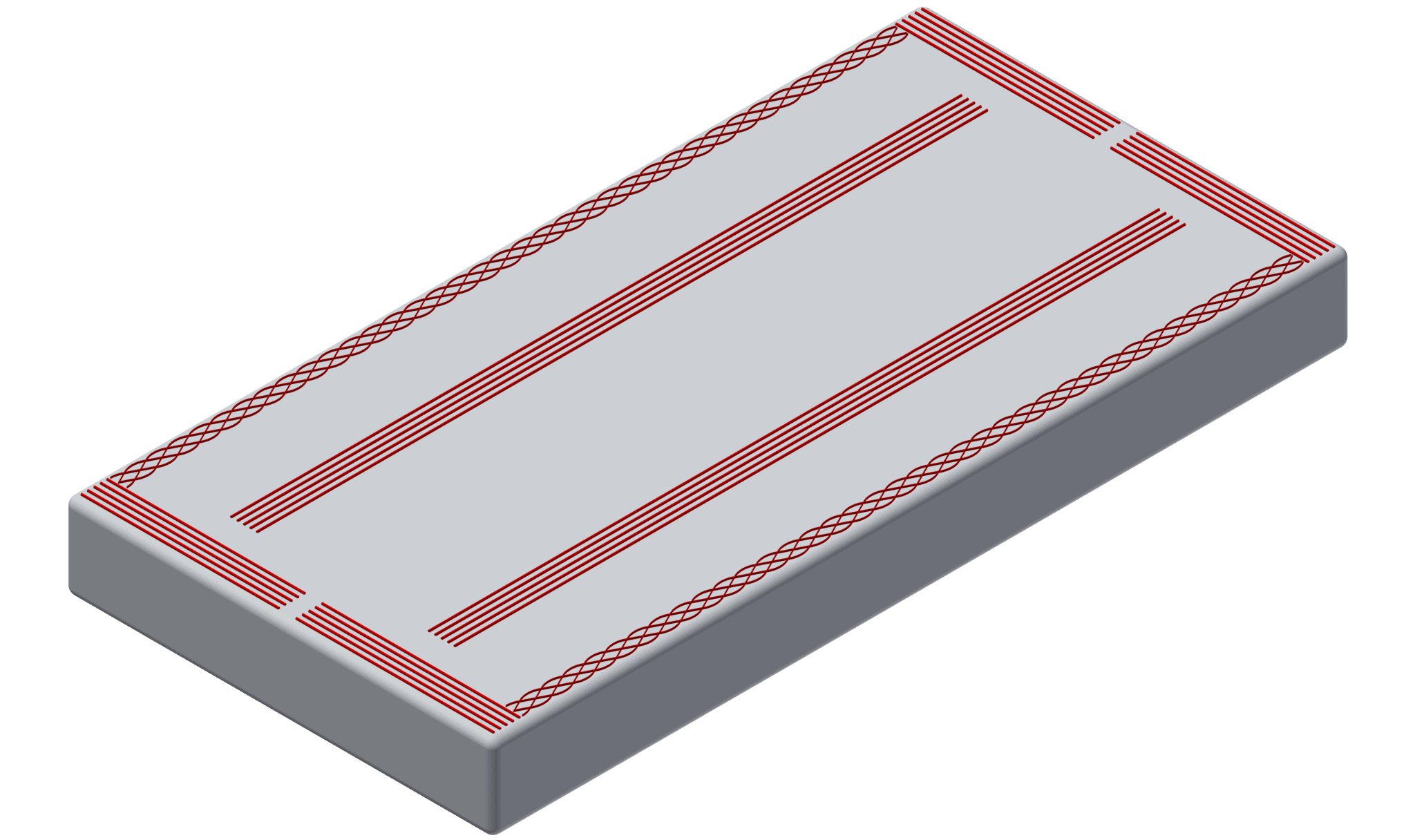

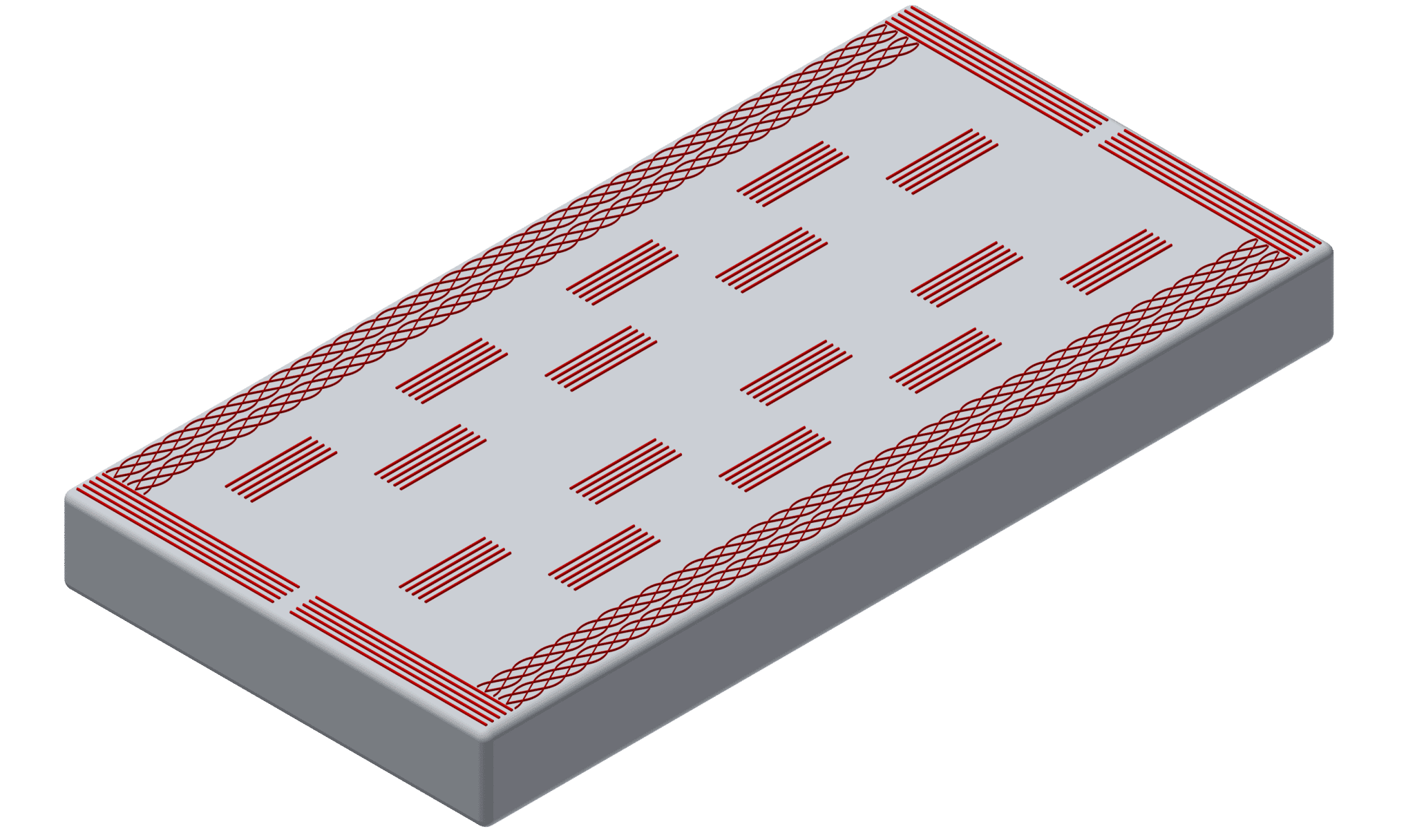

The adhesive is applied without spraying and without contact as a bead application in the form of the special Crossliner application in the longitudinal direction and in straight stripes in the longitudinal and transverse directions. The crossliner application increases the stability of the bonded joints.

The panels to be glued are conveyed from the alignment table via one or more conveyor belts (gluing belts) through the gluing system to the assembly tables. The adhesive is applied in the gluing cabin while the panel is being transported via the adhesive belts. Depending on the number of adhesive tracks to be applied, the panel can be moved back and forth several times.

The Crossliner gluing line can be used for the production of various types of multilayer padding.

The simple production of bonded mattresses and cushions made of foam, fleece, coconut fiberboard, felt, spring cores and barrel pocket spring cores are common applications of the Crossliner.

The highlights of our crossliner

- Contactless, spray-free adhesive application

- Increased tear-out resistance of the CROSSLINER application

- Automatic height, width and length adjustment

- Diverse combination of adhesive tracks due to freely programmable adhesive patterns

- Sequence of panels with different glue patterns possible

- Many mattress sizes can be realized

With proven and innovative technology we fulfill your wishes

Safety fencing of the gluing cabin

Safety doors with safety switches

additional middle nozzles for the application of stripes to the center of the panel;

Construction as a gluing line with assembly belts for manual mattress assembly and presses for intensifying the adhesive bonding.

step to the solution!

You can reach us in different ways, depending on which type of contact you prefer.